Valve Interlocks

Machinery Directive 2006/42/EC

We are proud to announce that our Valve Interlocks conform to the directive.

Valves have a prime safety function in many process industries. The opening and closing of valves in the wrong sequence can have disastrous consequences causing serious or fatal injury to operating personnel, loss of product, damage to plant and equipment and pollution of the environment.

Ensuring the safe operation of valves is essential in industries ranging from water and food production to chemical manufacture and oil refining.

The ISS Safety range of valve interlocks not only control the opening and closing sequence of process valves but also prevent their unauthorised operation. The interlocks are manufactured from stainless steel, maintenance free, tamperproof, robust, reliable, resistant to sand, dirt, snow, ice and moisture ingress, easy to operate, show clearly the condition of the valve and can be fitted to every type and size of valve in service without breaking the pressure seal.

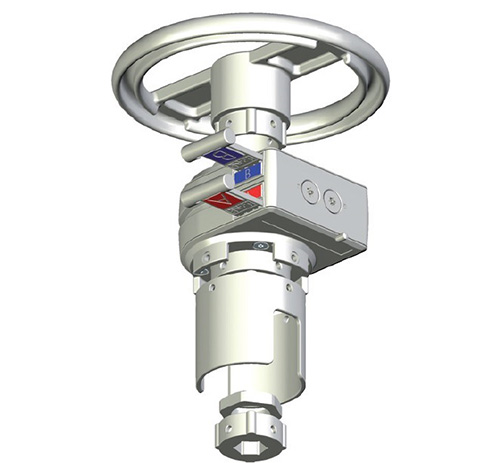

HSV-R

The HSV-R multi rotation valve interlock kit is suitable for all types and sizes of hand wheel-operated gate, globe and gearbox valves.

With both linear keys inserted into the lock the valve can be operated. Only when the valve is fully opened or closed can one of the keys be released, locking the valve in open or closed position.

Summary of key features:

- Manufactured from stainless steel AISI 316

- A hand wheel is provided in the same size as the original

- Robust, reliable and simple design with a minimum amount of parts

- Wide operating temperature range

- Self sealing key lock portion weather strips

- Fitted with anti tamper fixings

- Maintenance free

- Can be retro fitted to existing site valves without shutting down the plant or making modifications to the valve

- Tested to withstand the most extreme operating environments

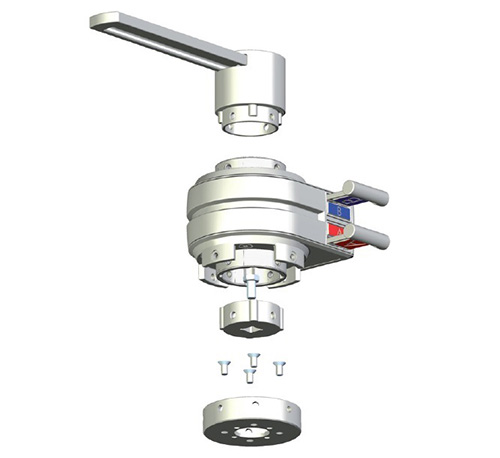

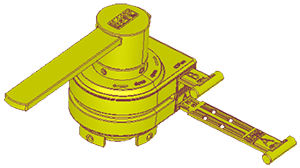

HSV-Q

The HSV-Q valve interlock kit for lever operated valves can be installed on any type and size of valve that operates with a 90° or 180° rotation i.e. ball, butterfly and plug valves.

With both linear keys inserted into the lock the valve can be operated. Only when the valve is fully opened or closed can one of the keys be released, locking the valve in opened or closed position

Summary of key features:

- Manufactured from stainless steel AISI 316

- A lever is provided in the same size as the original

- Robust, reliable and simple design with a minimum amount of parts

- Wide operating temperature range

- Omni directional key insertion

- Self sealing key lock portion weather strips

- Fitted with anti tamper fixings

- Maintenance free

- Can be retro fitted to existing site valves without shutting down the plant or making modifications to the valve

- Tested to withstand the most extreme operating environments

HSV-M-AT

The HSV anti tamper valve interlock kit has been specifically designed to prevent unauthorised operation, violation and sabotage of any size and type of valve including ball, butterfly, gate, globe, gear box, lever or hand wheel operated. In addition the AT includes a case hardened skirt to protect the lower valve assembly from sabotage or tampering. With the coded key removed the ATL lock free wheels ensuring the valve cannot be opened or closed depending on what the process requires. Inserting the key engages the drive allowing the valve to be operated.

Summary of key features:

- Manufactured from stainless steel AISI 316

- Hardened steel skirts to protect lower body of lock

- Wide operating temperature range

- Omni directional key insertion

- Self sealing key lock portion weather strips

- Fitted with anti tamper fixings

- Maintenance free

- Can be retro fitted to existing site valves

HSV-CL

The HSV-CL is a door access interlock designed to work with the HSV valve interlock system key. It is mainly used to control the safe opening and closing of cabinet or pig launching closure doors.

Pig launching and receiving is recognised as an extremely dangerous operation and is considered a primary hazard.

Multiple hazards prevail when loading or unloading a pig trap and include:

- Opening the trap door while the vessel is under pressure or 'on-stream'!

- Trying to pass a pig through a partially open outlet valve!

- H2S leaking to atmosphere!

A valve interlock system encompassing the main isolating valves, kicker, vent, drain and purge valves, as well as the vessel closure door will provide total operator and equipment safety and prevent the chance of the above hazards occurring.

The closure lock (CL) forms part of an interlocking sequence that ensure the isolation valves are closed and the vessel is vented and drained before opening the closure.

Since every closure is different the CL locks are custom designed for each type and size of closure. However the design philosophy behind the CL lock remains the same; in general, opening of a closure requires removal of a bleed-bolt. The closure lock prevents the bleed-bolt from being removed and thus preventing the closure from being opened. Only the insertion of a unique linear key releases the bleed-bolt enabling the closure door to be opened.

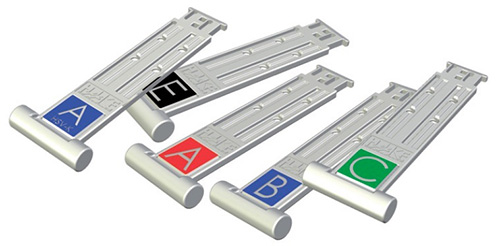

HSV-KEY

Manufactured of stainless steel the keys are coded in such a way that they only fit each designated valve interlock. Bespoke choice of engraving for each key is shown on the tag plate. The plates have space for four lines of text and are available in blue, red, black, white, yellow and green. This colour system simplifies matching the key to each interlock and clearly shows the condition of the valve from a distance.

Summary of key features:

- Manufactured from stainless steel AISI 316

- Ergonomic shape

- Tag plate available with four text lines

- Tag plate available in various colours

- Multiple coding options

- Omni directional key insertion

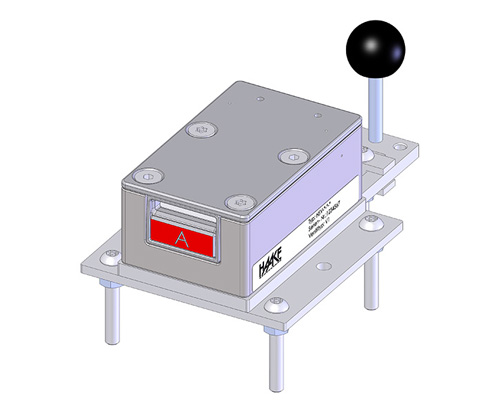

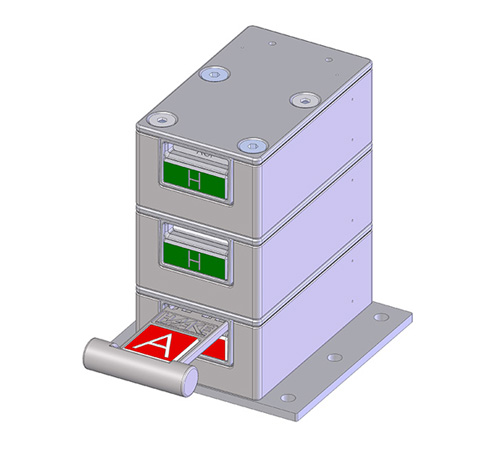

HSV-X

Many applications require the use of key exchange boxes as part of a valve interlock safety system. The key exchange box is configured to trap and release keys in a predetermined sequence depending on the operating requirements of the interlocking system. The key exchange box can be configured to provide bi-directional control of up-stream and down-stream operation. They can therefore be used in complex applications.

Summary of key features:

- Manufactured from stainless steel AISI 316

- For non linear key exchange applications

- Robust construction

- Maintenance free

- Omni directional key insertion

- Self sealing stainless steel key lock portion weather strips

- Fitted with anti tamper fixings

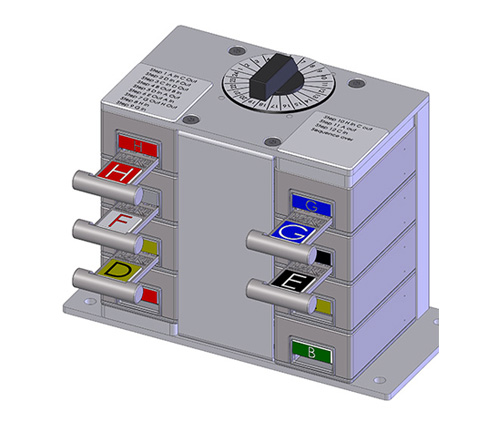

HSV-SCU

The SCU key selector unit is a mechanical programmed key exchange unit. It enables the release of the valve interlocking coded operating keys in a stepped sequence by rotating the selector control to the required key release position. The SCU is designed to provide the correct key exchange sequence in non–linear applications such as pig launching and receiving systems.

Summary of key features:

- For non linear key exchange applications

- Robust construction

- Manufactured from stainless steel AISI 316

- Maintenance free

- Omni directional key insertion

- Self sealing key lock portion weather strips

- Fitted with anti tamper fixings

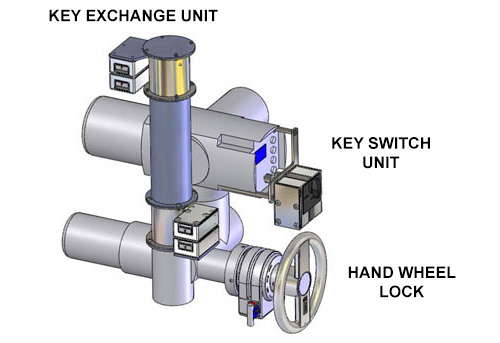

HSV-AV

In many applications actuators are used to control the opening and closing of valves.

Actuators can be activated, either from a remote or local position by an electric, hydraulic or pneumatic power source.

In all cases, when interlocking an actuated valve the interlocking system must be able to control the power and guarantee the position of the valve.

To control the opening and closing of an actuated valve, forming part of an interlocking system (for example the main trap valve on a pigging system), you are required to switch on or isolate the power to the actuator from a local position, prove the position of the valve under control and to operate the valve manually if required.

The control of an actuated valve can be achieved using three components from our valve interlocking range:

- Key exchange unit

- Key switch unit

- Hand wheel operated valve

Summary of key features:

- Manufactured from stainless steel AISI 316

- Robust, reliable and simple design with a minimum amount of parts

- Maintenance free

- Greased for life

- Tamperproof

- Mounting is very easy and can be done without shutting down the plant or making modifications to the valve

- Resistant to ingress of sand, dirt, snow, ice, and moisture

- Tested to withstand the most extreme operating environments

HSV-KC

The HSV-KC key cabinet is designed to enhance the control and management of valve interlocking keys on site by securely storing them in dedicated key slots within a locked cabinet. Each key slot is hard coded (a key cannot be physically inserted into the wrong slot), colour coded and engraved with the key tag number for easy identification and location. The glass front enables easy viewing of operational status of the valves within the system.

The key cabinet is available in a range of sizes storing from 1 to 144 system keys or spares. The key cabinets can also be fitted with mimic diagrams incorporating valve details from the P&ID to provide an overview of the valve control system. The key slots can also be fitted with electrical switches to provide status information.

Summary of key features:

- Robust construction

- Front door lock

- Optional switches for electrical signalling available

- Glassed door

- Custom built

- Powder coated resin finish – suitable for marine environment

STEP files available on request

Please contact us to receive a STEP (ISO 10303) file for use in your CAD project.